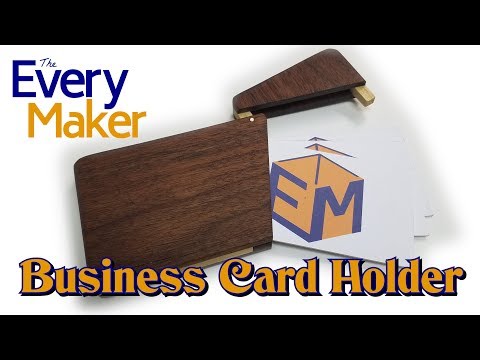

Welcome to the Every Maker. My name is Nick, and I got myself some business cards. I'm super happy with the way they came out, but I need a way to carry them with me. So, I'm going to make this little business card holder. I'm a hoarder, I keep pretty much all of my wood scraps, especially if it's hardwood. But today, it's time to go through those scraps and make a business card holder. I have some leftover walnut and Hickory from a long game I made for my wedding, and that's what I'm using today. I'm gonna use the Hickory for the edges. To start, I'm gonna clean up one of the edges of the board. Music. It's already the right thickness, but I need to cut it down to about a quarter of an inch for the width. One strip would probably be enough, it doesn't really take much, but I cut two just to make sure I have enough if I screw up. And yes, I did mess up. The walnut is going to be the face sides of the card holder. I started by cutting it down to width as well. I used the Hickory as spacers and lined up my business card to set up a stop block, making sure to leave a little bit extra in length, as I'll be cutting this board again for the lid. I cut both faces out individually, but if you are batching these out, you can cut an entire stack of boards. I carefully lined up where I wanted the faces cut for the lid and used two boards for the stop to keep them from slipping. Once the faces were all cut out, I used a flat board and some self-adhesive sandpaper to make sure...

Award-winning PDF software

Video instructions and help with filling out and completing Form 8815 Cardholder